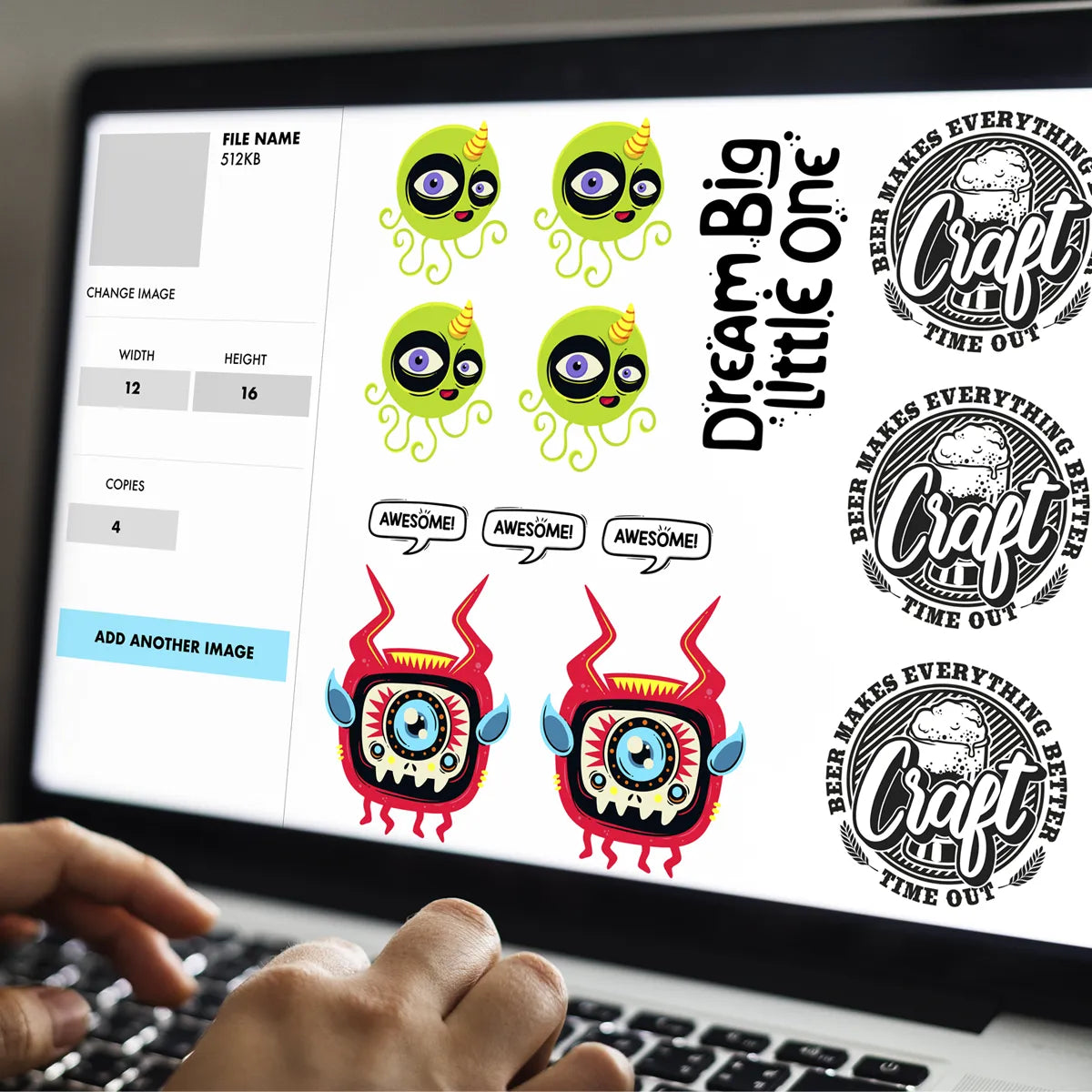

DTF Transfer Options

DTF Transfer Options

Blog Article

knowing the Necessities allows make certain good results in DTF transfer jobs. Here is an in depth overview of the necessary equipment:

get rid of: The film containing the powdered design ought to be heated beside activate the adhesive powder. This can be achieved in the use of a warmth press, curing oven, or conveyor dryer.

With DTF warmth transfers, the setup time and labor are minimal, which may result in quicker turnaround times for your orders.

You demand a warmth press to complete DTF printing. the warmth press is used to transfer the layouts over the PET films onto the desired area for printing. Heat and pressure aid the transfer process.

Artwork with Tremendous little aspects or slim strains might also sometimes pose challenges, as the quantity of backing adhesive might not be ample to adhere towards your clothes without some sort of alterations.

The DTF transfer process starts with printing your style onto a PET film utilizing a specialised printer. This printer takes advantage of CMYK shades and white ink to produce a lively graphic.

Exactly what are the care Guidance for DTF transfers? hold out 24 several hours right before your first clean, then use device wash chilly with mild detergent.

4. Curing: The film is then cured using a warmth push or oven. This phase is critical as it makes sure that the adhesive solidifies and the look is ready to be transferred.

You can utilize Completely ready-created types or create custom models in the digital natural environment making use of layout software package. Transfer your style and design to your DTF printer to perform the printing.

contemplate print area just like the sq. footage of a household. Too much coverage results in a heavy print that is not breathable, also called a "sweat patch."

Yellowing of adhesive or waffle texture about the copyright is possible and standard; this can not influence software.

the appliance of heat leads to the adhesive powder to soften and adhere to the ink, creating a good, transferable DTF Transfers layer.

The film which has the printed design and style on it's the DTF transfer. You can then implement this DTF transfer sheet to the fabric material utilizing a warmth press. DTF transfers could be applied to a range of types of garment kinds:

subsequent, you'll want to feed your design in to the DTF printer. The DTF printer works by using inkjet know-how to transfer the look onto a PET movie.

Report this page